Electrical Inspections,

Surveys & Repair Services for the Oil & Gas Industry

Pentland Energy is now primed to provide risk mitigation procedures involving electrical and Instrumentation equipment domiciled in hazardous environments in a way that is fully compliant with your 60079 legislation: IECEx domestically & ATEX internationally.

Fire and Gas Detection

We understand the desire of our Industrial clients to have a proactive & effective streamlined flame and combustible/toxic gas hazard mitigation system/process in place

We guarantee both on the strength of flexibility, functionality, reliability, and conformance to highest Internationally approved industry standards.

We will convey our core competitive Engineering competence and application expertise across your oil platforms, FPSOs, petrochemical facilities, R&D centers, aircraft hangars, gas transport loading terminals, pipeline pumping stations, refineries, LV/MV/Grid systems, Feeder substations/plants, Industrial Automation & Control systems, IT Power & Data Centers, Green Energy stations and Critical Power systems and many more, within a 20-day cycle for each Project.

Fire and Gas Survey Scope

Visual inspection of Fire & Gas (FG) detection panel components as per Installation wiring conditions and system drawings

Checking of main/emergency (UPS) power feeding F&G systems

Visual inspection for FG detection modules & panel wiring conditions as per system drawings

Repair Services for all Fire and Gas Detection Systems

Function test of all manual call points (MCPs) in a loop or zone

Visual inspection of HMI/Displays

Testing of all localized H2S – and LEL – gas sensors

Sounder & Beacon inspections

Localized testing of all smoke and heat detectors using relevant, appropriate test kits

Function test of alarms through PA/GA system if integrated

Configuration checks with regards to Fire system and Gas panel system etc.

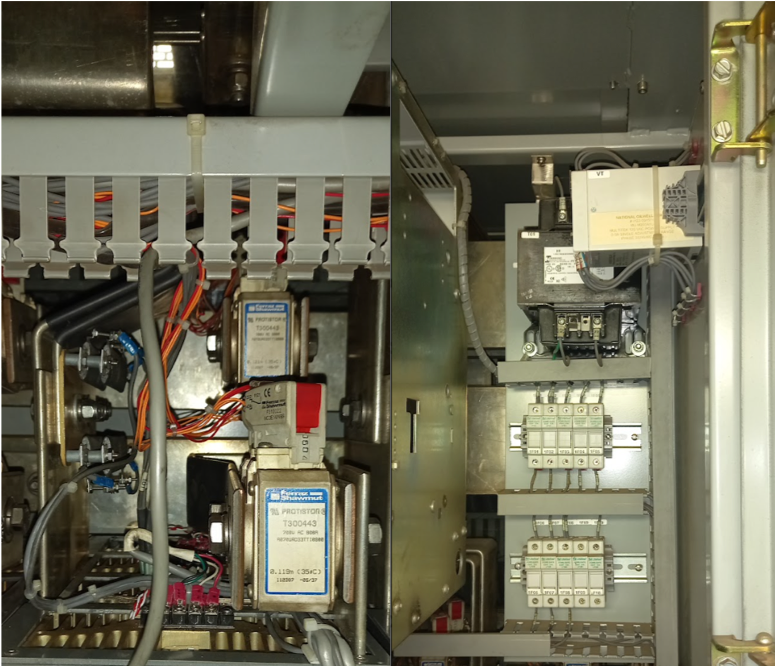

SCR Integrity Survey

The SCR Health check work scope includes but not limited to Inspecting and testing/checking the following on Rigs and Platforms

- Generator control cubicles: visual inspection.

- AC Module signal check

- Silicon Control Rectifiers Control Cubicles: visual inspection.

- DC Module signal check

- Motor control center & Auxiliary circuits: visual inspection

- Driller's, Mud Pump & TDS Consoles: visual inspection

- Preview of CIT report

- SCR Inventory

Current Injection Testing

At Pentland Energy, we know how critical the Current injection testing process is From troubleshooting and corrective maintenance of your entire Electrical protection system to the commissioning and maintenance of your substations and switchgears - We're here to make sure that your breakers properly protect your electrical equipment!

We can conduct a complete system test on all your circuit breakers with static trip devices

- MV/HV/LV circuit breakers trip in response to an overcurrent – CHECK

- Correct wiring or mating of the contact surfaces and pivot points of the protection system – CHECK

- Overcurrent and earth fault relays – CHECK

- Verification that all switches and protective relays receive the proper current at the proper angle as expected – CHECK

- Testing ground grid installations

- Testing of reclosers and sectionalizers

- Thermal tests on busbars, switchgear and electrical panels and much more